-

Galvanized Structural is coming!

Our galvanizing plant is officially put into production with an annual production capacity of 500,000

Contact : 513 254 0135

/

e-mail : Info@NorthAmericaMetalsInc.com

Your reliable steel supplier

North America Metals, Inc. (NAMI)

Providing Quality Materials Since 2013

Our Products & Services

Popular Products

Structural Steel

Full ranges ASTM A36, A572, A992 Steel beams, Angles, Channel and steel tubes, galvanized also available.

Coils & Sheet

We can deliver galvanized, galvanneal, stainless, Tinplate and aluminum flat rolled products, sheets or in coils.

Heavy Plate

ASTM carbon plate, thickness from 6mm up to 50mm, width from 1524 up to 2438mm, length range from 6096 to 12192mm.

Steel Tube

NAMI supplies its customers with all types of steel tubing including A500 and A847 rectangular and square carbon steel structural tubing. NAMI is your best steel tube supplier

Steel Bars

NAMI offers hot rolled and cold rolled flat, Round bar, Rectangle bar, Square bar and rebar. Specialty large diameter round bars are also available.

Stainless and Aluminum

NAMI stocks a wide inventory of stainless and aluminum products such as sheet, angle, tubing and more. Stainless: 3xx and 4xx series and Aluminum: 5xxx, 6xxx series.

We Are Specialist For

Many Services

Financing Services

The company’s essential growth and development is dependent upon its healthy relationships with banks and financial institutions in the USA and China. Our mission is to ensure strong financial position and capabilities to structure the trade finance, which creates the ability to meet our suppliers and customers needs. Open terms to customer net 30, 45, even up to 90 days after cargo arrival. We also assist our clients in obtaining higher credit lines and provide them with sufficient funds so that they can focus on their marketing areas with peace of mind.

Supplier Chain Management

NAMI creates solutions for its customers in order to determine the most suitable suppliers and help to place an order. Making sure that our customers receive the products with the desired quality, tailored payment terms and at the best possible price are the priority for our supply chain management services. We produce steel products in advance according to our customers’ seasonal or annual purchasing plans and store them in warehouses near customers. Customers can quickly get the steel they need. No need for long wait. Being on time is our top priority

Exclusive Sales Services

NAMI is acting as an exclusive distributor of steel mills for North and South American markets. The long-term distribution contracts maximize trade benefits for both suppliers and consumers. Our suppliers can rely on the stable demand for their steel products, while we effectively manage logistics and financial services. Our consumers can concentrate on their core business knowing they are always covered with supplies and everyone gets the savings from freight, financing, prices and insurance. Contact us for more details on exclusive sales services.

About us

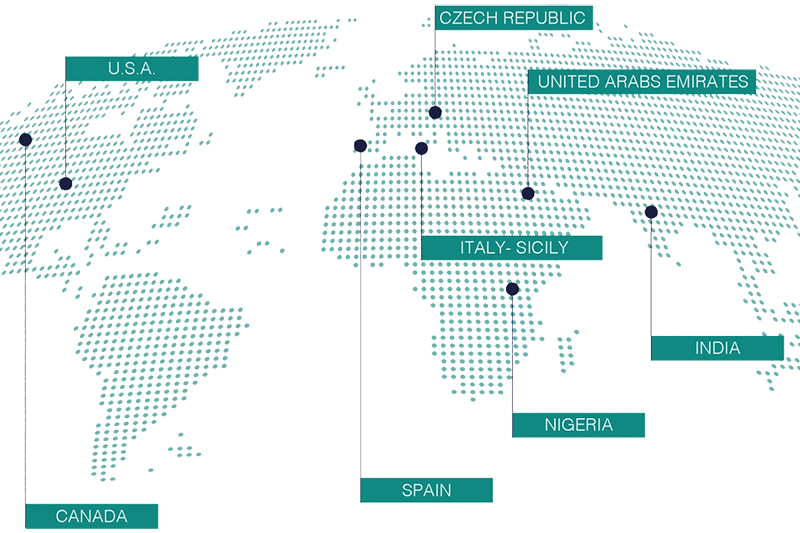

North America Metals, Inc (NAMI). was established in 2010. We provide a full range of steel products to customers around the world, including steel sections, hot-rolled plates, hot-rolled coils, cold-rolled coils, galvanized coils, color-coated coils, stainless steel, aluminum alloy and other steel products. We shipped millions ton of steel yearly, and our steel materials cover Japanese standards (JIS), British standards (BS) and American standards (ASTM). Our products meet the needs of international markets, including Europe, North America, the Middle East and South America.

Our team boasts years of expertise in steel mill operations, managing deliveries, customer acquisition and relationship building, documentation handling, vessel chartering, part cargo shipping, financing, cargo and payment insurance, production planning, and order follow-up from the melt shop to our customer’s warehouse.

Logistics control in house

Shipments on time is our top priority

NAMI’s logistics team work with loading port and vessel owner directly

We do everything in house and in person at the mills and at the ports

Quality Control

Inspection is the key

Precision

Our team strictly inspect each steel we shipped

Seriously

High quality requirements

Professional

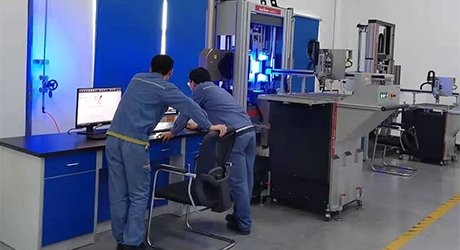

Our precision instrument testing center

In Production Line

When the steel mill produces our steel, our production engineers with 30 years of experience and our quality inspectors will be stationed at the mill to closely inspect every stage of the production process, ensuring that each batch of steel is of high quality.

In The Laboratory

Our laboratory team will randomly take samples back to the lab during the production process to test the steel. We will check the mechanical properties, tensile strength, and various physical and chemical elements to ensure they meet the required standards.

When loading

The loading and unloading of steel during transportation is a very important task. To avoid any damage to the steel during transit, our logistics team will assist with the loading and unloading at the dock site until the steel is safely loaded into the ship’s hold.

From Our Blog